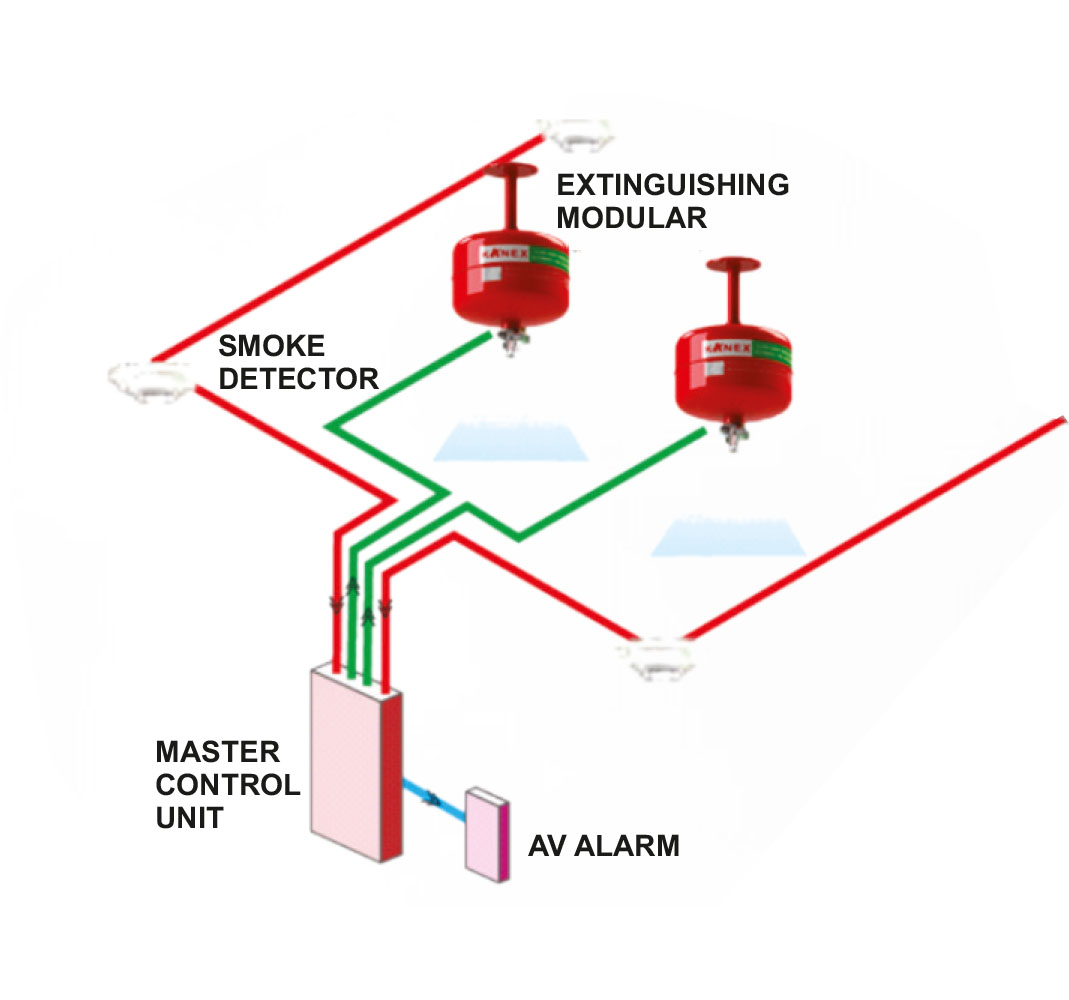

FIRELITE® AUTOSAFE SUPPRESSION System is a suppression solution designed for unmanned rooms where manual intervention at early stages of fire is not possible. This automatically operating suppression system is ideally suited for small server rooms and storage areas e.t.c where special attention is required in providing adequate protection against fire hazard with early detection and suppression without causing any collateral damage. This system comprises of ceiling mounted cylinder filled with Clean Agent and integrated with an electrically actuated control valve, Point detectors and Fire Detection and Alarm panel. In case of fire, the detector sends signal to the fire alarm panel, which triggers the electrical actuator on the cylinder valve to discharge the agent into the room thereby suppressing

| Item Code | UOM | Discription |

|---|---|---|

| RPS0001 | NOS | Flange Assembly |

| RPS0002 | NOS | Extention Bar |

| RPS0003 | NOS | Pressure Guage |

| RPS0004 | NOS | 0.5 sqmm X 2 core Cable |

| RPS0005 | NOS | Mounting Adaptor |

| RPS0006 | NOS | Sprinkler |

| RPS0007 | NOS | Solenoid Valve |

| RPS0008 | NOS | O ring |

| RPS0009 | NOS | Smoke Detector |

| RPS0010 | NOS | Fire Alarm Panel (Model no RE 120GR) |

| Item Code | Part Discription | H (MM) | D (MM) | Working Pressure | Approx Gross Weight | Volume Protection |

|---|---|---|---|---|---|---|

| FG086 | 10 kg FIRELITE AUTOSAFE SUPPRESSION SYSTEM | 486 (+_10) | 300 | 15 Bar | 17 Kg | 2.5M3 |

| FG087 | 15 Kg FIRELITE AUTOSAFE SUPPRESSION SYSTEM | 486 (+_10) | 400 | 15 Bar | 24 Kg | 6M3 |

| FG088 | 20 Kg FIRELITEAUTOSAFE SUPPRESSION SYSTEM | 506 (+-10) | 400 | 15 Bar | 32 Kg | 10M3 |

| FG089 | 25 Kg FIRELITE AUTOSAFE SUPPRESSION SYSTEM | 524 (+-10) | 400 | 15 Bar | 39 Kg | 15M3 |

| Technical Data | Product Application | |

|---|---|---|

| Extinguishing Agent | Fk1230 (FK-5-1-12) | This System can be used, but are not Limited, |

| Propellant | Nitrogen | to protection following |

| color | Red | |

| operating Temp | -30 ⁰C to + 60 ⁰C | Server Room |

| Test pressure | 35 bar for 60 sec | Electrical Panel Room |

| Burts pressure | 55 bar at body, 80 bar at weld | UPS Room |

| Filling Tolerance | ± 5% by mass | ATMS |

| Material | Meter Rooms E.t.c. |

Fire extinguishers should be located throughout the workplace and readily accessible to the employees without subjecting them to possible injury. Selection and installation vary site to site and hazard to hazard. General Placement distance as per the class of fire as per IS 2190 is mentioned below;

The knowledge of operating fire safety equipment and how to act during a fire emergency is of utmost importance as it equips the employees with the knowledge and skills to about the fire emergency procedures. Fire safety training shall be carried out every 12 months. In some critical circumstances, organization shall provide additional training. Factors that may prompt this include: An incident occurs in your industry/workplace, which impacts on your business and safety procedures.

Preparation is the key to an effective response to workplace fires. Fire drills are ways to prepare for exiting a building or performing emergency procedures during a fire emergency. Fire drills help prepare employees to respond quickly, calmly, and safely. Fire & emergency drills shall be conducted, in accordance with the Fire Safety Plan, at least once every six months.

Flammable liquids, solvents and gases, waste products, combustible materials, Oxidising chemicals, Pyrotechnics, Sparks, Hot work, Extractor fans, Conventional heat sources like HVAC and radiators, Frictional heat and static from machinery, electrical hazards due to exposed wires, overloaded circuits, static discharge and extension cords, faulty electrical equipment and machinery, activities such as welding and grinding, and anything that involves molten metals, etc. are an identified fire risks in an industrial environment.

Flammable liquids, solvents and gas storage, combustible material waste, Uncovered or unprotected fuel, electrical circuits, heating equipment, and smoking materials can also cause fires. Fire potential is less for Warehouse when compared to the industry. But when a fire incident occurs happens it is on a massive scale.

While you might think that your office is free from combustibles because there are no oils, gases or open flames, there are still risks present in any commercial building. Paper, wooden furniture, plastics, tissues, cleaning liquids, and even dust can catch fire. Electrical hazards such as exposed wires, overloaded circuits, extension cords, faulty electrical equipment and unprotected combustible materials are the primary risks for a fire breakout in offices.

Fire safety standards generally focus on minimizing the reaction to fire of products and materials used in different living environments such as domestic dwellings, household equipment, furnishings and electronics, buildings and different transport modes. Globally, most fire safety regulations have policies and procedures in effectively storing, managing, and disposing of fire initiating materials or activities. Different fire standards such as NFPA, NBC, BIS etc. are followed by the organizations for fire safety compliance.

BIS (Bureau of Indian Standards) has a guideline mentioning a small band of distinguishing color shall be prominently visible on the surface area of fire extinguishers. As you are aware that different types of extinguisher are suitable for specific classes of fire, band colour identifies the type of fire extinguisher and its suitability on different classes of fire.

The most feasible fire safety equipment required to have are fire extinguishers. The fire extinguisher equipment should be easily identifiable, highly visible, easily accessible, adequately charged, and regularly inspected. They should be placed high on wall surfaces and positioned near to the closest exit.

A fire risk assessment is a review undertaken of a building, office premises, or commercial complex in order to assess its fire risk and offer recommendations to make the building safer. It is a legal requirement. Any structure where people are dwelling as part of a commercial activity must have this done. The risk assessment is done by a fire safety authority from local fire service department with fire safety education, training and experience.

A qualified fire authority inspects a premise as part of a periodic fire risk assessment. The enforcement officer evaluates the fire standard compliance at the workplace and identifies the potential areas of improvement. The evaluations also reinforce the policies to ensure that no fire accident happens. The inspection verifies the efficiency of the existing fire prevention measures.